Displaying items by tag: Oil Analysis

High 5 for Hitachi!

WearCheck’s laboratories in Gauteng recently welcomed new clients Hitachi Ltd., who signed up for condition monitoring services - in particular, oil analysis - for their mining and construction operations across the African continent.

The Japanese-based company focuses on social innovation across a range of business sectors, including power and infrastructure systems, information and telecommunication systems, construction machinery, high functional materials and components, automotive systems, healthcare and others.

Hitachi has engaged WearCheck as a support chain partner in the development of their oil analysis programme.

Delegates from Hitachi Ltd. recently attended an oil analysis training course in Johannesburg, run by WearCheck’s technical manager, Steven Lumley

Just plane condition monitoring...

Just plane condition monitoring . . . the WearCheck brand reached new heights recently where the company logo holds pride of place on the fuselage and wings of one of the aircraft of an air acrobatics team sponsored by holding company Torre Industries. Look out for the plane flying over various sporting events in the greater Gauteng area!

Mining Indaba

WearCheck was once again present at Mining Indaba 2017 recently, where many people came to the stand to chat about condition monitoring. This year, WearCheck shared a stand with sister company Set Point Laboratories (SPL), which is also part of holding company Torre Analytical Services.

Standing by to discuss the latest trends in oil analysis and other reliability solutions techniques were (from left) WearCheck MD Neil Robinson and technical manager Steven Lumley. With them (right) is Johan Botes, CEO of Torre Industries, which owns Torre Analytical Services

WearCheck Training. Africa & Beyond.

Ghana, Zimbabwe

WearCheck training manager Ashley Mayer conducts oil analysis courses for South African customers as well as those in exotic locations. Recently, he travelled to West Africa and Zimbabwe to offer training courses.

Ashley Mayer (front row under banner, blue shirt) is seen with African Mining Services delegates who attended an oil analysis course at a mine site in Zimbabwe recently.

Workers from AngloGold’s Ashanti site at Iduapriem in Ghana listen attentively to WearCheck training manager Ashley Mayer.

Abu Dhabi, Dubai

Steven Lumley, WearCheck technical manager, travelled to the Middle East to attend a conference and to run some training courses for customers in the region. She conducted a training course for employees of the NDC (National Drilling Corporation) of Abu Dhabi, and a course for Al Shirawi employees in Dubai.

Steven Lumley talks delegates through water contamination and oil analysis in Abu Dhabi recently.

Steven Lumley conducted oil analysis training for delegates of Al Shirawi in Dubai recently. She is pictured here (third from right) with some of her students.

Train for Productivity

As oil analysis and reliability solutions are increasingly complex fields which are constantly evolving with new technology, WearCheck offers a variety of training courses for several levels of staff, targeted at workers in the maintenance and management arenas.

WEARCHECK 2017 OIL ANALYSIS TRAINING COURSES

Efficiency, speed and reducing the need to redo tasks – these are just some of excellent returns on investment for businesses that train their employees to do their jobs competently.

This is reinforced through the words of management guru Peter Drucker, ‘If you think training is expensive, try ignorance.’

Oil Analysis One covers two full days and costs R5 540. Oil Analysis Two and the NetCheck course cover one full day each and each costs R2 795.

Courses include course material, lunch, refreshments, giveaways and certificates. Prices exclude VAT and are subject to change. All courses can also be presented at the customer’s premises for a minimum of six delegates.

Other on-site courses: WearCheck Practical (in English or Zulu), a half day course costing R650 plus VAT per delegate, and WearCheck Customised – oil analysis for workshop technicians, a full day course costing R1 525 plus VAT per delegate.

For on-site training, there may be an additional charge for the lecturer’s travel and accommodation, if needed.

Training courses can be arranged anywhere.

For more details on course content, view Training at www.wearcheck.co.za. For bookings phone Kay Meyrick on (031) 700-5460 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

RELIABILITY SOLUTIONS TRAINING COURSES

Mobius training is offered in 153 countries, and is recognised the world over as the preferred standard for reliability solutions technicians. Mobius courses are run by WearCheck and presented either on-site or at the ABB School of Maintenance premises.

Courses include Alignment, Balancing, Awareness, and CAT I to III, and costs (excl VAT) are as follows, when presented at the ABB venue at 2 Lake Road, Longmeadow Business Park, Modderfontein, Johannesburg, South Africa.:

Courses can be presented on-site, and will be quoted accordingly

To book any of the above courses, or get course dates for the second half of 2017, please contact Dennis Swanepoel on 082 878-1578 or email This email address is being protected from spambots. You need JavaScript enabled to view it., or contact Christene Fourie on (011) 392-6322 or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Bulletin 62: Measuring and treating varnish formation in turbine oils

Varnish deposits can cause absolute havoc when they form in turbine oils, control valves and other machinery components, often leading to severe interruption to the smooth operation of the system.

Therefore, early detection of an oil’s varnish-forming potential is key to maintaining components operating at their optimum level. At WearCheck, we conduct a host of tests on turbine oil to measure its varnish-forming potential and also to determine the oil’s remaining useful life.

Once an oil is contaminated with varnish, the oil cannot simply be changed. The varnish must be removed properly, and the cause of the varnish formation identified, in order to prevent or minimise future varnish formation.

To learn more about measuring varnish-forming potential, effective ways to remove varnish, and how to identify the root cause of the varnish formation, please click here to view Technical Bulletin 62.

We're EXHIBITING!

Mining Indaba is the world’s largest mining investment conference taking place at the ICC in Cape Town from the 8th – 11th February 2016.

As WearCheck enters its 40th year of business, we will once again be attending the conference and exhibiting at the show, so please be sure to visit our stand and gain some insight into the world of Condition Monitoring.

We will be showcasing the following products

-

Oil Analysis

-

Fuel Analysis

-

Filter & Grease Analysis

-

Coolant Analysis

-

Vibration Monitoring

-

Thermal Imaging

-

Laser Alignment & Balancing

WearCheck Stand Number 304, Hall 2

For more information on the show visit www.miningindaba.com

WearCheck Monitor 61

Oil analysis prevents equipment failure for Atlantis Mining

Oil analysis by WearCheck Africa proved instrumental in avoiding machine failure on two of Middelburg mining contractor Atlantis Mining’s earthmoving units recently by detecting component wear in time.

All of the Middelburg-based mining contractors’ fleet Caterpillar, Komatsu, Hitachi, Volvo and Terex equipment have been on WearCheck’s oil analysis programme for the past 12 years.

On this occasion, one of the machines was a Caterpillar D9T bulldozer where samples on both final drives were diagnosed by WearCheck as borderline. The oil was resampled and drained but the samples came back as borderline again. Atlantis resampled the new oil after 100 hours in use and submitted this to WearCheck. Again the sample was borderline.

Critical sample

‘The misleading factor was that the magnetic plugs showed no signs of contamination,’ said Mark Johnstone, managing director of Atlantis Mining. ‘We continued to run the machine whilst monitoring the final drive oil samples until we were advised of a critical sample at 9028 hours. Again the magnetic plug showed no signs of contamination, but it was decided that the final drives should be opened.’

Machine failure avoided

Three weeks later the workshop removed the final drives at 9192 hours. On disassembly it was found that the inner bearing had started to ‘pit’ and that the wear was starting to go through the hard facing. All the bearings were replaced and a major failure was avoided.

‘This was thanks to our successful oil sampling programme, accurate diagnosis by Wearcheck technicians and timeous action,’ Johnstone said.

‘Knowing that we can rely on our oil analysis programme gives us peace of mind, particularly as we are working with machines that are costly to replace and where equipment downtime quickly eats into profits. It is a cost-effective conditioning monitoring tool that has proved its worth time and time again.’

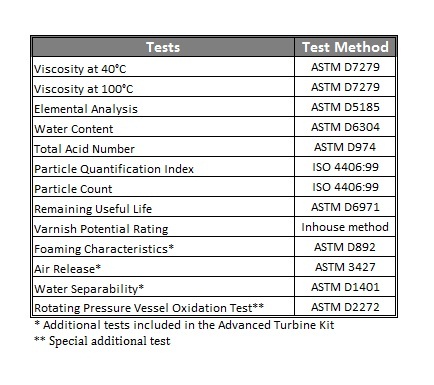

New product: Turbine Oil Analysis

The performance of the oil in a turbine application is vital in many aspects to ensure reliable performance of your turbine. WearCheck's Turbine Oil Analysis kits have been designed to measure the core functions of the oil and give you the ability to monitor the operating condition of the oil and hence conduct scheduled proactive maintenance procedures.

In today's world companies rely on turbines and compressors to provide power and gas transportation for core processes. Turbines and compressors already have demanding lubrication requirements and those demands are increasing. More demands are being put on these fluids as reservoir size and working clearances decrease and system power outputs, pressures, temperatures and oil service life increase. Lubricants must be highly oxidative and thermally stable to be able to handle operating temperatures. Additionally the lubricant must remain contaminant free to properly lubricate bearings and gears, and to act as a favourable hydraulic medium for governors and valving systems.

Oil oxidation and sludge will lead to sticking servo valves, meaning control valves will not open on demand. Oil contamination will accelerate wear, cause governors and valves to operate erratically and plug system filters. Unmonitored, poor oil condition leads to unplanned outages which are extremely expensive.

In order to achieve peace of mind on the operating condition of your turbine and compressor you need the comprehensive testing that WearCheck provides. Specifically designed for industrial turbines and compressors, WearCheck's Turbine Oil Analysis kit combines well established industrial tests with more recent advances in industry testing to provide an unparallel view of the operating condition of your critical lubricates.

WearCheck's Turbine Oil Analysis kit determines the levels of remaining antioxidants in the oil, detects for unwanted oil contamination and will accurately determine the suitability of the lubricant for continued use. A comprehensive diagnosis will warn you of any potential for damaging varnish build up and include recommendation for any necessary maintenance actions to remove contamination and restore the lubricant to optimum operating condition.

Tests include

Typical Applications

- Gas turbines

- Steam turbines

- Hydro-electric turbines

- Rotary compressors

For more infomation contact WearCheck on +27(0) 31 700 5460 This email address is being protected from spambots. You need JavaScript enabled to view it. or download brochure.