Displaying items by tag: Turbine Oil Analysis

New product: Turbine Oil Analysis

The performance of the oil in a turbine application is vital in many aspects to ensure reliable performance of your turbine. WearCheck's Turbine Oil Analysis kits have been designed to measure the core functions of the oil and give you the ability to monitor the operating condition of the oil and hence conduct scheduled proactive maintenance procedures.

In today's world companies rely on turbines and compressors to provide power and gas transportation for core processes. Turbines and compressors already have demanding lubrication requirements and those demands are increasing. More demands are being put on these fluids as reservoir size and working clearances decrease and system power outputs, pressures, temperatures and oil service life increase. Lubricants must be highly oxidative and thermally stable to be able to handle operating temperatures. Additionally the lubricant must remain contaminant free to properly lubricate bearings and gears, and to act as a favourable hydraulic medium for governors and valving systems.

Oil oxidation and sludge will lead to sticking servo valves, meaning control valves will not open on demand. Oil contamination will accelerate wear, cause governors and valves to operate erratically and plug system filters. Unmonitored, poor oil condition leads to unplanned outages which are extremely expensive.

In order to achieve peace of mind on the operating condition of your turbine and compressor you need the comprehensive testing that WearCheck provides. Specifically designed for industrial turbines and compressors, WearCheck's Turbine Oil Analysis kit combines well established industrial tests with more recent advances in industry testing to provide an unparallel view of the operating condition of your critical lubricates.

WearCheck's Turbine Oil Analysis kit determines the levels of remaining antioxidants in the oil, detects for unwanted oil contamination and will accurately determine the suitability of the lubricant for continued use. A comprehensive diagnosis will warn you of any potential for damaging varnish build up and include recommendation for any necessary maintenance actions to remove contamination and restore the lubricant to optimum operating condition.

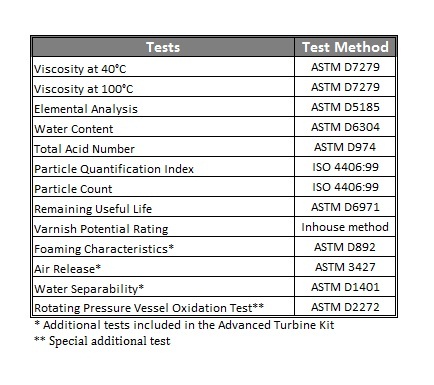

Tests include

Typical Applications

- Gas turbines

- Steam turbines

- Hydro-electric turbines

- Rotary compressors

For more infomation contact WearCheck on +27(0) 31 700 5460 This email address is being protected from spambots. You need JavaScript enabled to view it. or download brochure.