Displaying items by tag: Silicon

Silicon... Enemy number one. Part 2.

Using oil analysis to detect dust early.

Before the use of oil analysis, a dust entry problem would go undetected until a routine strip down or a failure occurred. Even then, often the wear would be attributed to lubricant breakdown or normal wear and tear. With the use of oil analysis, the picture changes. As soon as a dust entry problem occurs there is an increase in the silicon level of the oil and an acceleration of the wear pattern. As long as the oil samples are being taken at regular intervals in the correct manner, the dust entry will be detected at a very early stage. If effective corrective action is taken, the life of the component will be significantly increased, reducing maintenance costs.

It is beyond the scope of this article to discuss every type of dust damage in all components, so engines will be used as an example. Engines are at high risk to dust entry as large volumes of air are taken into the system and the close tolerances make it susceptible to even the smallest dust particle.

When an engine has a dust entry problem, the type of wear that takes place is related to the manner in which the dust enters. Therefore, by examining the type of wear taking place, it is possible to discover how the dust is entering the system. When studying an oil analysis report there are four possible wear patterns:

- Normal wear

- Increased top-end wear

- Increased bottom-end wear

- All wear rates increased

Image: Engine air cleaner system

1. Normal wear

It is unlikely that there will be a dust entry problem without an increase in wear rates. If normal wear patterns combine with high silicon readings, there are two main possibilities:

-

A silicone sealant, grease or additive is in use

-

Accidental contamination of the sample

Action to be taken

Check if an additive, grease or sealants have been used recently on the engine.

If no, check if correct sampling technique was used.

If yes, phone lab to confirm that additive can cause high silicon reading. If necessary, send sample to confirm.

If there is still doubt as to what caused the high silicon reading, a check sample should be taken.

Was the oil changed when the first sample was taken?

If no, send a check sample and, as a precaution, change the oil.

If yes, send a check sample only after the engine has run for 50 hours or 1000km.

2. Increased top-end wear

Increased top-end wear is caused by airborne dust that has been drawn into the combustion chamber being forced between the ring, piston and cylinder. This is caused by a defective air cleaner or a damaged induction system.

Action to be taken

Inspect the air filter element thoroughly, and check its seals and support frame for damage and distortion. Check the pleats for damage. If there is any doubt about a filter element, it should always be changed.

Next, check the induction hosing for damage, cracks, etc. and make certain that all hose clamps are secure. The breather and compressor are often connected to the induction system but are frequently overlooked. Check that both are functioning normally and their hoses are sound and secure.

Next, check the inlet manifold for cracks, and check that the gaskets are sound and secure.

Was a leak found?

If no, run the engine at idle and block off the air intake. The engine should stall within three seconds. If the engine does not stall, listen carefully at the joints for air being sucked in. Take a check sample after 50 hours or 1000km.

If yes, determine the condition of the engine. Check compression and blow-by. Repair the leak.

If normal, monitor the oil consumption as a safeguard.

If abnormal, schedule to have the piston rings replaced and the piston and liners examined.

3. Increased bottom-end wear

This indicates that dirt is getting into the lube oil directly and not past the piston and rings. The likely sources are:

-

Leaking seals

-

Defective breather

-

Damaged seal on oil filler cap or dipstick

-

Dirty storage containers and/or top-up containers

Action to be taken

Any dust which is in the oil will be pumped through the oil filter before entering the bearings. Therefore the first step is to examine the oil filter for:

-

Dust contamination

-

Bearing material

Was excessive dust found?

If no, check the sampling technique. Examine the oil filter at the next service.

Was bearing material found?

If no, monitor oil pressure and inspect the oil filter at the next service.

If yes, drop the sump and inspect all bearings. Replace as necessary

If yes, thoroughly check all seals and breathers, etc. Check the oil storage containers and top-up containers for the source of contamination.

4. All wear rates increased

This is the worst case. Carry out checks for top and bottom wear. Several other checks must also be done:

-

Was any repair work done to the engine? It is possible that the increased wear rates are due to a “rebedding in” process and silicon comes from contamination while the engine was open for repairs.

-

Piston torching. This is a rare occurrence but if a piston is torched by a misdirected or badly timed spray from an injector nozzle, silicon is released from the piston itself and all the wear rates will be increased. (Silicon is alloyed to aluminum to reduce its rate of expansion.)

For further infomation please contact WearCheck on +27(0) 31 700 5460 or This email address is being protected from spambots. You need JavaScript enabled to view it.

Silicon... Enemy number one.

External contamination of lube oil by silicon (dust) is a major cause of accelerated wear.

After oxygen, silicon is the most abundant element in the earth’s crust. Silicon does not occur naturally in elemental form but rather combined with oxygen in a compound called silica (silicon dioxide.) Silicon occurs in a free form (quartz, sand, etc.) or combined with a variety of metallic oxides, in which case it is called silicate (eg. Felspar).

Another class of silicon compounds that should not be confused with silica and silicates is silicones. Silicones are man-made organic compounds that find extensive application in the polish, paint and lubrication industries.

Silica and silicates make up a large proportion of the earth’s crust and as such are present at high concentrations in natural solids and dusts. It is for this reason that silicon is used as the main indicator of dust entry into a component. There have been several studies done on the causes of premature wear in components. The figures vary from study to study but one thing is clear: external contamination of lube oil by silicon (dust) is a major cause of accelerated wear.

The South African climate generally is one of low rainfall with resultant high dust levels. Particles of airborne sand and dust vary in size, shape and abrasive properties. In an engine the ingress of atmospheric dust takes place primarily through the air intake. Efficient air filters remove 99% of the dust that an engine ingests.

Image: Dust particles

The remaining 1% consists of very small dust particles that pass through the air filter. These vary between submicron size particles to particles up to 10 microns in size. The dust will pass between piston, rings and cylinder and eventually become suspended in the lubricating oil.

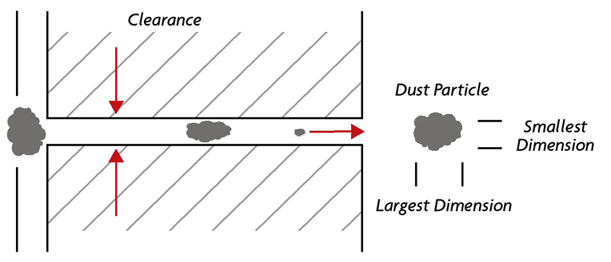

It is the particle that has its smallest dimension of a similar size to the clearance involved that does the maximum damage. A particle smaller than the clearance will pass straight through doing little harm. A particle larger than clearance will be unable to enter and do any damage. (See diagram above)

In an engine the clearance between the piston ring and liner bore is extremely small, therefore it is the small light airborne dust particles which are the biggest threat when a leak occurs in the induction system.

Under ideal conditions the working surfaces of a component are kept apart by a thin film of oil. This oil film prevents direct contact between the surfaces, reducing the amount of friction and the rate of wear. The oil film will also absorb shock loads and help distribute the load over the whole surface. The introduction of even a small amount of dust into this environment will seriously disrupt this. Once the dust particle has entered the oil film it forms a direct link between the two surfaces, nullifying the effects of the oil film.

The first and immediate effect is a “scratching” of the surface as the particle is dragged and rolled across the surfaces. The second and potentially more serious problem is that once the dust particles is introduced in between the two surfaces, it changes the loading of the surface from an even distribution to a point load concentration on the particle with tremendous increase in pressure at this point.

The increase in pressure causes a deflection of the surface, which will eventually result in metal fatigue and the surface breaking up.

The solution is to keep the dust out. To do this, design engineers use air cleaners, breathers and seals at any point that dust may enter.

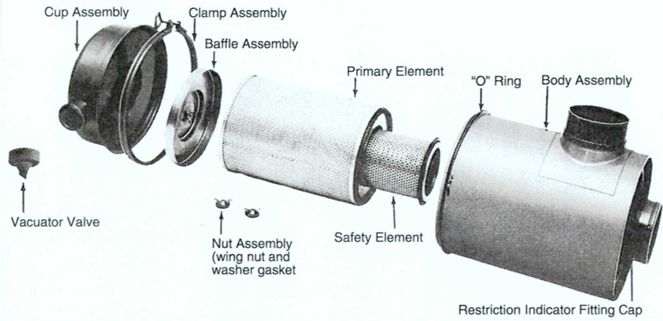

Air cleaners filter air as it is drawn through a system, e.g. in engines, compressors, etc. They have to deal with large volumes of air, as an engine needs up to 2000 litres of air to burn 1 litre of fuel efficiently. The most common type of air cleaners have three main components: a centrifugal precleaner, a large pleated paper element, and a smaller paper or cloth “safety element”.

The precleaner consists of radial fins and a collection bowl. The fins cause incoming air to swirl rapidly around the inside of the housing. The heavier dust particles are thrown outward by centrifugal force and are channelled into the dust collection bowl. Some bowls have an automatic discharge valve; other bowls have to be removed from time to time to clean out the accumulated debris before its overflows into the filter housing.

The main filter element traps the remaining dust particles as the air is drawn through the paper pleats.

The smaller safety element is fitted after the main element in case the main element is damaged in any way. Its purpose is to trap any dust introduction when the main filter is changed. It does not filter as effectively, however, nor can it hold the same volume of dust.

Image: Air cleaner

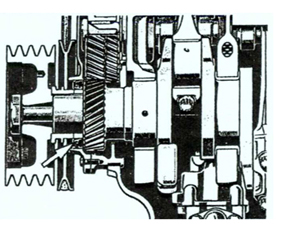

Breathers are used to allow air to flow in and out of a component. As a components temperature increases in operation, the internal air expands with the increase in temperature with a resultant increase in pressure. If this air was not allowed to vent to the atmosphere, the build-up in pressure would force the air out at the weakest point, normally the seals. As the component cools down after operations, air is once again drawn in through the breather. If it is unable to draw in air, for example if the breather is blocked, then air will be pulled in past the seals with the danger that it may draw dust into the seal at the same time.

Seals prevent oil from entering or leaking out of a component wherever there is a danger of this happening. There are many different types of seals in use today, but as a rule of thumb “if oil can get out, dust can get in”. A leaking seal should always be replaced.

Images: Engine breather of turbocharged engine & front crackshaft oil seal.

End of part one...