Displaying items by tag: WearCheck News

Zapper arrives at WearCheck

WearCheck customers can now pay with the Zapper mobile application when purchasing any WearCheck products and services from the following branches - KZN, Gauteng, Middleburg and Cape Town.

Zapper is a free app which enables you to charge items to your credit card without having the credit card physically present at the transaction. Zapper is very secure, and works on any smart phone or device. Simply download the app, load in your credit card details and start zapping!

When presented with an invoice, you simply open the Zapper app, and scan the QR (quick reader) code located at the branch. The QR Code can also be emailed upfront to you, to allow you to process the payment before you arrange collection of your WearCheck products.

Once the user scans the QR code with their smart phone and approves the transaction and the amount, the money is debited directly off the user’s credit card. Zapper does not charge the user to use the app.

You will receive an email from Zapper confirming the transaction.

An example of a QR code:

scan this one (via the Zapper app) with your smart phone just for fun, it will take you to the WearCheck website.

Dedicated for two decades

One of the things that makes WearCheck stand head and shoulders above its competitors is the people that work for the company, and the great rapport they have with our customers and with their colleagues.

This rapport is not developed overnight, but rather, it is nurtured and grown over time, and WearCheck is fortunate to have many dedicated team members who have worked for the company for long stretches of time.

HR manager Michelle Padayachee praised the long-serving staff members who have dedicated their energy to the company and applauded the loyalty of all long-serving staff members. ‘We appreciate your dedication and recognise your commitment to the company – thank you.’

Michelle noted several team members who have now been with WearCheck for two decades.

Image:

- Managing director Neil Robinson has been at WearCheck for 20 years. He began his career with the company as a chemist in 1997, was promoted to lab manager in 1999 then technical manager in 2002. He has lead the company as MD for the past 12 years.

- Field service customer support officer Isaac Mabaso has worked at WearCheck’s Johannesburg branch for 20 years

- Laboratory assistant Shireen Brijlal has worked in WearCheck Pinetown’s lab for 20 years

- Software support assistant Collin Naicker has worked at WearCheck Pinetown for 20 years

- Reliability solutions lead technician Eddie Pieterse, fondly known as “Eddie Senior”, has worked at this job for 20 years. Eddie was part of WearCheck’s ABB acquisition in 2012.

- Credit supervisor Kay Pillay has worked at WearCheck Pinetown for 20 years

WearCheck passes audit with flying colours

WearCheck recently underwent its annual audit by a customer - Siemens - where the audit scope was on occupational health, safety, environment and quality. The auditors rated WearCheck as “excellent”, with a score of 99,56%.

While the entire company and its systems are reviewed, the WearCheck team liaising with the auditors consisted of quality administrator Prinda Narasi, managing director Neil Robinson and laboratory manager Meshach Govender.

The auditors had this to say in their report: “A well-defined and mature system was found to be in place and communication thereof, accessibility and knowledge were found to be well-ingrained within the company.”

Well done, WearCheck!

WearCheck MD Neil Robinson, along with quality administrator Prinda Narasi and laboratory manager Meshach Govender, liaised with Siemens during the

annual audit recently.

Budding scientists visit WearCheck

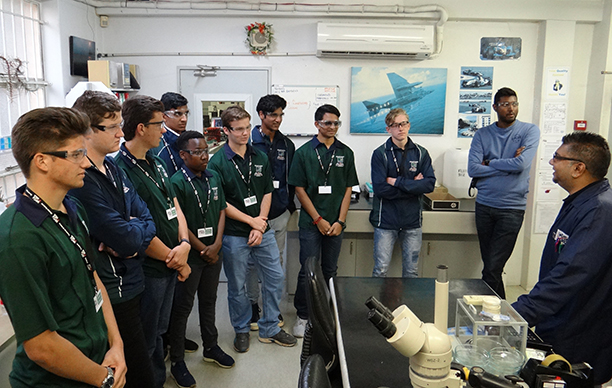

36 grade 11 pupils from Curro Grantleigh High School in Richards Bay recently visited WearCheck’s Pinetown laboratory to further their studies in chemistry by learning about condition monitoring.

The students were hosted by WearCheck technical manager Steven Lumley, who explained the workings of the main laboratory to them. They also heard a presentation on oil analysis by diagnostician Quinton Verster and toured the mini-laboratory, witnessed science experiments, learned about important safety procedures and visited the outbuildings where waste oil and other fluids are processed according to the company’s strict environmental standards.

Grantleigh teacher Andrew Meintjies reported that the science learners really benefited from the visit. ‘It was really important for the students to see how the theory that they are learning at school is being applied and just how relevant it is to industry/society today.’

Grade 11 students from Curro Grantleigh High School in Richards Bay travelled a long way to learn about condition monitoring at WearCheck recently. Here, staff and students gather outside the company’s Pinetown branch.

Field and lab technician Shashay Rampersad of WearCheck demonstrates some of the wet chemistry performed on aircraft oil filters in the mini-lab in Pinetown, to a group of Richards Bay learners from Curro Grantleigh High School, on a recent visit.

WearCheck wins new contract

ArcelorMittal South Africa (AMSA) - the largest steel producer on the African continent – has awarded WearCheck the contract for the provision of the analysis of transformer oil samples at AMSA.

In the letter of confirmation from AMSA, the group manager for IPS and group contracts had this to say, ‘Following a comprehensive evaluation and consideration of proposals submitted to us, your proposal has been successfully nominated.

‘We would like to take this opportunity to thank your staff for the comprehensive manner in which the information was presented.’

Earlier this year, WearCheck bought Transformer Chemistry Services (TCS) and brought TCS MD Ian Gray on board to run the new transformer services division. TCS has had the contract to service the ArcelorMittal transformers since 2005, and the new contract with WearCheck bears testament to AMSA’s satisfaction with the service from TCS.

During a recent audit of WearCheck by AMSA, WearCheck scored highly as a vendor of AMSA.

AMSA has the production capacity of around 7 million tonnes of liquid steel per annum, supplies over 61% of steel used in South Africa, and exports the balance.

AMSA attributes its success to ‘ongoing alignment with international best practices … ensuring the company’s continued global competitiveness and participation in international markets.’

Says Ian, ‘We at WearCheck are honoured to be selected to service AMSA’s transformers, and guarantee that our usual standards of excellence are aligned with AMSA’s best-practice ethos.’

WearCheck welcomes a very special visitor

From small beginnings as a soil-testing business based in the garage of founder Lesley Crawford and her business partner Gary Brown over 40 years ago, WearCheck has grown into one of the leading condition monitoring companies on the African continent today.

Lesley, who now lives in France, made a special visit to the company on a recent trip back to South Africa. As many of the current employees in the Pinetown branch were already employed by the time Lesley left the company in 2005, her visit was a happy reunion for these folk. Newer staff members enjoyed getting to meet the amazing lady whose foresight, scientific knowledge and business acumen helped set WearCheck onto a growth course that still hasn’t ended.

Managing director Neil Robinson presented her with some WearCheck memorabilia to celebrate the company’s 40th birthday, including a book on the history of WearCheck, a commemorative latte glass and, of course, some cake.

Out and about

WearCheck staff members from various branches have clocked up some big air-miles lately, attending conferences, meetings and expos in several countries to stay abreast with the latest technology and to learn more about the evolving needs of industry.

WACA

The annual West and Central African Mining Summit & Expo (WACA) takes place in Accra, Ghana. This year, the WearCheck guys who were on-site to meet prospective customers and to talk condition monitoring, included Daniel Boakye, manager of WearCheck Ghana, and Pierre de Villiers, senior technician.

MINEX

Iran hosted the 5th annual Mines and Mining Industry Expo (MINEX), featuring the latest mining innovations for Iran and the Middle East. This year, WearCheck was present for the first time. Managing director Neil Robinson and Peter Safadi, manager of WearCheck PM Dubai were on hand to meet delegates. Neil was interviewed by an Iranian TV station, where he talked about condition monitoring.

WearCheck MD Neil Robinson is interviewed by Iranian TV at this year’s MINEX show in Tehran.

Seen at MINEX in Iran recently were Peter Safadi of WearCheck PM Dubai, Kevin Gerber of Set Point Laboratories and Neil Robinson, WearCheck MD.

MENA

The Middle East Mining Congress (MENA) once again took place in Dubai recently. This expo, which features “everything mining”, was attended by WearCheck for the first time.

On hand to meet and greet delegates at MENA in Dubai, were Peter Safadi (WearCheck PM Dubai manager), Steven Lumley (technical manager), Ingy Elazizi and MD Neil Robinson.

WINDABA

Wind energy is a burgeoning source of alternative power, and the focus of Windaba, as Africa’s premier Wind Energy Conference, dovetails well with WearCheck’s wind turbine condition monitoring programme. Attending Cape Town’s 2016 Windaba expo from WearCheck were Steven Lumley (technical manager), diagnostician Quintin Verster and reliability solutions manager Philip Schutte.

Loyalty Recognised

WearCheck is a family of very dedicated and loyal staff members, many of whom have clocked up several decades with the company. HR Manager Michelle Padayachee commended all long-serving staff, particularly those who reached important milestones recently.

‘Your loyalty and experience benefits both the company as well as our customers – helping us to continue to run the business efficiently and to offer excellent customer service. Thank you for your loyalty.’

Captions:

Image 1: Springs-based reliability solutions technician Frank Nkuna has worked at WearCheck for 10 years.

Image 2: Pinetown lab assistant Malcolm Govender has worked at WearCheck for 15 years.

Image 3: Isando-based reliability solutions technician Marcelle Symons has worked at WearCheck for 10 years.

Image 4: Ellisras-based reliability solutions technician Simon Mosima has worked at WearCheck for 10 years.

Image 5: Johannesburg-based driver Danny Nkomo has worked at WearCheck for 10 years.

Prestigious peer review

WearCheck's diagnostic manager, John Evans, who - in his more than 25 years with the company - has had many of his articles published in many scientific journals in several countries, has diagnosed over a million samples, has conducted many training courses and is widely recognised as an inveterate expert in the oil analysis field.

WearCheck, and John, were recently honoured when John was invited to conduct a peer review on a manual chapter written by two American scientists, entitled "Particle Counting: Fuels and Lubricants" for the ASTM-Books.

Reviewing papers for publication is perhaps the highest mark of respect bestowed upon a researcher. To be asked to review a scientific paper is an acknowledgment of a researcher's superior knowledge and experience.

Well done, John, you have done WearCheck proud.

Monitor Issue 73

2016 was a busy year indeed for WearCheck...celebrating 40 years of condition monitoring excellence, reaching an important SABS milestone, attending many international and local conferences and expos and installing some high-tech new laboratory equipment.

Have a look at Monitor 73 to read more about these stories, as well as WearCheck’s popular new bypass filter, and find the answer to the question on everyone’s lips…WHO won the fabulous Samsung tablet? (The lucky draw prize for the customer services survey respondents)!

Under the Technical Tip section diagnostics manager John Evans explains in detail how to react to your sample report.

Click here to read about these and other stories.